Plastic recycling is the process of recovering scrap or waste plastic and reprocessing the material into useful products. According to U.S. Environmental Protection Agency (EPA), only 10% of the U.S. municipal solid waste stream is being recycled, and the rest is being accumulated in landfills or dumped into the natural environment as litter.

There are two basic approaches to the reuse of plastics: (1) mechanical recycling, and (2) chemical recycling. Mechanical recycling is a method by which waste materials are recycled into secondary raw materials without changing the basic structure of the material.

Recycling is critical for effective end-of-life plastic management. Operational efficiency will be supported by ongoing investment in research and development. Recycling of a greater range of post-consumer plastic products and packaging will further boost recycling and divert more end-of-life plastic wastes from landfills.

In chemical recycling, a plastic polymer is broken down into its constituent monomer. This process is called depolymerization. The monomers are used as raw materials for manufacturing a new polymer. This method can transform the plastic material into smaller molecules, suitable for use as feedstock materials starting with monomers, or mixtures of other hydrocarbon compounds. Various technologies have been developed to depolymerize plastics to produce fuel grade products. Only a few chemical methods such as pyrolysis and gasification have reached commercial maturity. Other technologies such as methanolysis, hydrolysis, glycolysis and hydrogenation are still being developed to improve the recovery of plastic waste.

In pyrolysis, plastic waste is heated in the absence of oxygen, which produces a mixture of oil similar to crude oil. This can be further refined into transportation fuels. Gasification involves heating the waste plastic with air or steam, to produce syngas. This can then be used to produce fuels or chemicals, or burned directly in boilers to generate electricity. A large benefit of gasification-based recycling of plastics compared to pyrolysis, is the possibility of utilizing mixtures of different types of plastics, or plastics mixed with other types of feedstock, e.g., biomass.

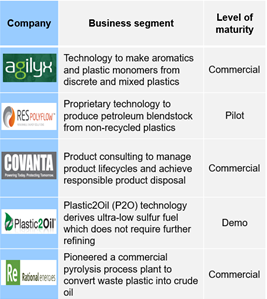

Consumer product and energy majors have taken steps to curb plastic waste to protect the environment. The Alliance to End Plastic Waste, which includes Chevron, Dow, ExxonMobil, LyondellBasell, Procter & Gamble, Shell, Total, Veolia plans to focus its resources on developing waste collection infrastructure, innovating in recycling and product design, educating consumers about waste, and cleaning up plastic in the environment. Innovations to convert plastic debris into refined fuel products are still in a nascent phase, with companies, including startups, looking to scale up. Figure 1 shows an illustrative list of companies involved in plastic recycling industry.

Exhibit 1: Illustrative list of Plastic Recycling Companies.

ADI’s Chemical Market Resources has done a lot of work across the global chemical and petrochemical value chain. We have been following the current global trends in plastic recycling industry. Please contact us to learn more.

— Utkarsh Gupta and Uday Turaga