Polypropylene (PP) is the most used plastic after polyethylene and has made way into our daily lives ranging from packaging and food containers to clothing, furniture, and automotives. PP is made via polymerization of propylene in the presence of catalyst, and it has benefitted largely through the catalyst development efforts that began with Natta, who discovered how to produce isostatic PP from Ziegler’s catalyst systems. For the past 50 years, one of the foundations of polyolefins manufacturing has been the Ziegler-Natta (ZN) catalysts, and PP is predominantly produced using ZN catalysts.

Five generations of ZN catalysts have characterized the development of highly improved PP resins. While the first two generations are almost extinct, the third generation is in the decline phase and is finding limited use. The fourth-generation catalysts based on the phthalate internal donors are the most popularly used, producing a wide variety of PP resins. In addition to using phthalate esters as internal donors, these use alkoxysilanes as external donors to increase the isostatic index (II) of resultant PP up to 97-99%, catalyst activity to 40-70 kgPP/gcat.h, and molecular weight distribution to 6-8 with low catalyst decay.

However, several health risks posed from phthalates in objects of daily use have been identified over the last few years including

- Health issues in children and adolescents, such as obesity, allergies, and asthma

- Increased risk of type II diabetes and insulin resistance

- Potential to initiate breast cancer

- Adverse impact on reproductive health

- Higher risk of loss of pregnancy

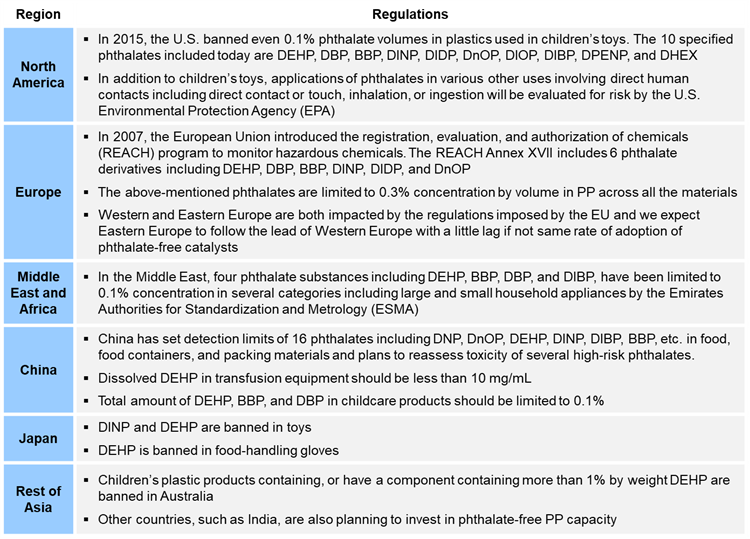

Citing these risks, several government and regulatory agencies globally are limiting phthalate concentration in objects which directly impacts their use in PP catalysts.

Exhibit 1. Regulatory measures banning phthalates by region

Fifth- and sixth-generation ZN catalysts are phthalate free catalysts. Although these catalysts provide 20% to 30% more activity than fourth generation catalysts, higher prices are slowing down adoption in developing economies. While developed economies have already imposed several restrictions on phthalates, the regulatory environment is expected to get more stringent going forward. As more capacity is added and prices of phthalate-free catalysts become competitive, adoption in developing economies is also expected to grow.

ADI Chemical Market Resources (ADI CMR) recently published a multiclient study on polypropylene catalysts that studies the impact of regulations on the demand of phthalate-free catalysts. ADI CMR also has a multiclient study on polyolefin catalysts landscape. Contact us to learn more.