LDPE Resin Technologies

High-pressure low-density polyethylene (HP-LDPE or LDPE) and copolymers of LDPE with ethylene vinyl acetate (EVA) are manufactured in a high-pressure reactor. Although this manufacturing process has traditionally been higher cost and more capacity restricted than the processes used to make linear-low density polyethylene (LLDPE), improved technologies make LDPE cost competitive with LLDPE. LDPEs, with their highly branched molecular structures, offer some benefits compared to LLDPE, such as higher melt strength, which creates stability in blown film processing and in making foams, for example. LDPEs and EVAs also generally have higher clarity and sealability than LLDPE. Metallocene-catalyzed LLDPE (mLLDPE) is a competitive technology to LDPE and EVA. This processing technology creates LLDPE with better clarity and lower seal initiation temperature than conventional LLDPEs, but better physical properties than conventional LLDPE or LDPE. Metallocene-catalyzed polyolefin elastomers (mPOEs) and plastomers (mPOPs) also compete with LDPE and EVAs.

Market Drivers in the LDPE Resin Market

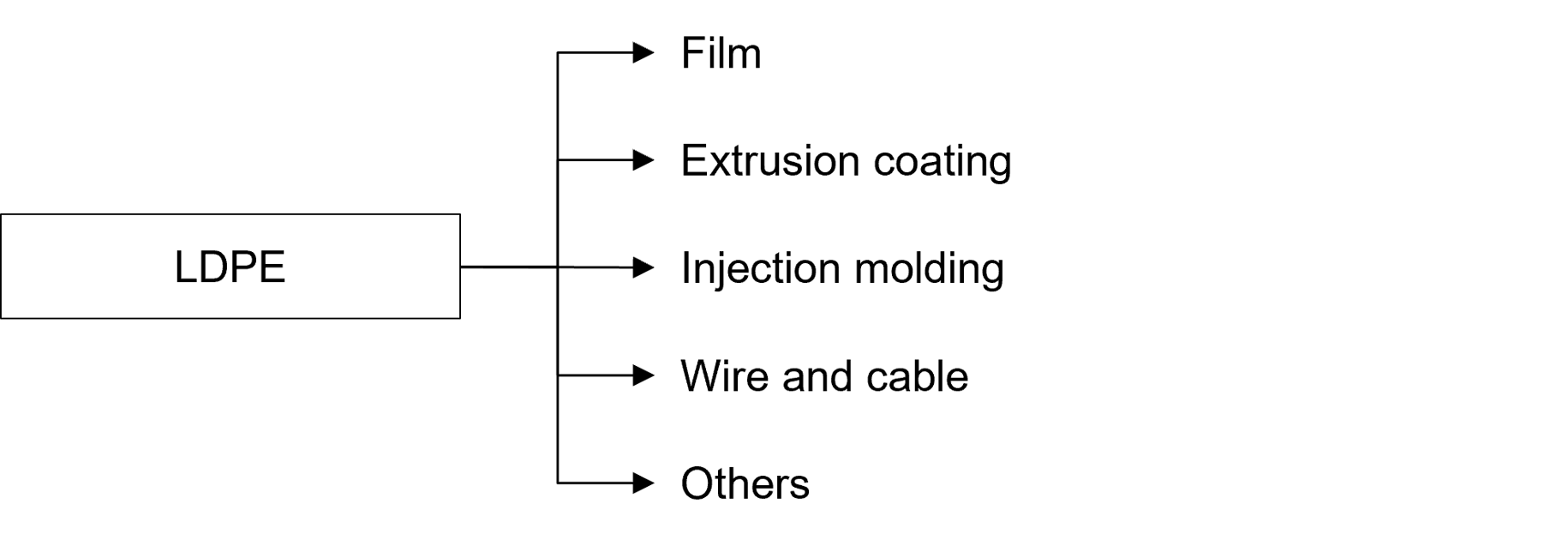

LDPE is used in many applications (see figure below). The largest market is film applications (e.g., bags, stretch films, packaging). Other areas include injection molded parts, extrusion coating, adhesives and sealants, and wire and cable. Metallocene-catalyzed LLDPEs compete with LDPE, and mPOEs and POPs compete with EVAs in applications including solar encapsulation. The exhibit shows key LDPE end-use applications.

Exhibit 1. Key LDPE end-use applications

LDPE Resin Market Assessment

ADI Chemical Market Resources (ADI CMR) has conducted a strategic analysis that covers all major developments in the industry including changing market dynamics, technology trends, evolving industry structure and strategic alliances, and the current and expected competitive landscape, with a renewed emphasis on the emerging regions. Market forecasts are presented by region and application for the next five years with a vision of the next 10 years. The report is based on thorough analysis of the industry through a wide range of methods, including published information, patent searches, ADI CMR proprietary projects, and interviews with leading suppliers, film converters, and major end-users in each market segment. Manufacturing cost economics and pricing structures are based on ADI CMR’s extensive cost databases and interviews. The geographic focus of the market assessment will be regions segmented into North America, South America, Europe, Middle East and Africa, China, Japan, and Rest of Asia. The report will particularly benefit producers, compounders, and packaging industry participants, as well as individual end-users, entrepreneurs, and organizations attempting to understand these complex issues and capture future growth in the marketplace.

Table of Contents

Click here to view the table of contents for this report.

Prospectus

Please fill this form and check your email for a link to download the prospectus. For a custom report on a topic of your choice or an updated version of an existing report, please contact us at +1 (281) 506-8234 or info@adi-cmr.com.