Metallocene-Catalyzed POE and POP Resin Technologies

Ethylene-based polyolefin elastomers (POEs) and plastomers (POPs) are copolymers of ethylene and other alpha-olefins such as butene, hexene, and octene with particularly flexible “elastic” and “plastic” properties. Ethylene-based POEs and POPs are made using single-site metallocene catalysts with a transition metal, such as titanium or zirconium, sandwiched between one or more cyclopentadienyl rings. These catalysts came into commercial use for making polyolefin resins in the late 1990s. ADI CMR’s report on polyolefin catalysts describes the catalyst technologies in more detail. POEs and POPs can be described as thermoplastic elastomers (TPEs), because they are thermoplastics with rubber-like properties. POEs and POPs, however, are made in the reactor and thus differ from conventional TPEs and thermoplastic polyolefins (TPOs), which are compounds or blends with a hard and soft phase. In fact, POEs and POPs can be used as the soft phase in a conventional TPO. ADI CMR has another report covering TPOs. ADI CMR classifies POE and POP based on density; POEs have densities less than 0.885 g/cm3 and POPs have densities of 0.885-0.910 g/cm3.

Market Drivers in the Polyolefin Elastomers and Plastomers Market

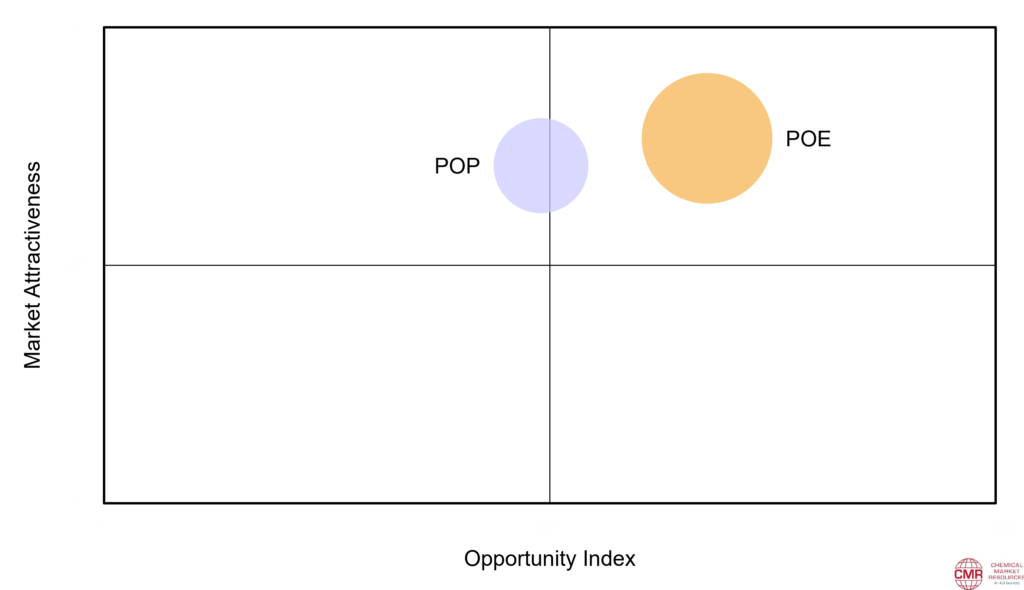

POEs have been used in the automotive industry and are now increasingly used to make hot-melt adhesives (HMAs) and encapsulants for solar panels, where they compete with high EVAs. POEs are also used in foam (eg, for footwear), wire and cable jacketing, industrial and construction applications, and medical applications. POPs are used for packaging, with many approved for food packaging, such as meat and cheese packaging or stand-up-pouches. POPs are also used for stretch and shrink films, in wire and cable, and as polymer modifiers. China has seen the highest share and growth in POE demand, while North America followed by Europe have the highest share of the global POP market. Exhibit1 shows attractiveness and opportunity index for the global polyolefin elastomers and plastomers market.

Exhibit 1. Market attractiveness versus opportunity index for polyolefin elastomers and plastomers

Polyolefin Elastomers and Plastomers Market Assessment

ADI Chemical Market Resources (ADI CMR) has conducted a strategic analysis that covers all major developments in the industry including a comprehensive analysis of supply-demand balance, status of technology availability, and strategic partnerships. It also gives extensive coverage on emerging players and challenges. The report is based on thorough analysis of the industry through a wide range of methods, including published information, patent searches, ADI CMR proprietary projects, and interviews with leading players including POE and POP producers, linear alpha-olefin producers, major converters, and end-users. Robust predictive models were created to forecast market size and attractiveness based on input from experts and experienced ADI CMR analysts. Models will forecast demand and supply through 2035. The report will include a global analysis of pricing and production costs, segmented by region and end-use applications, that predicts pricing up to 2035. The report will particularly benefit producers as well as individual end-users, entrepreneurs, and organizations attempting to understand these complex issues and capture future growth in the marketplace.

Table of Contents

Click here to view the table of contents for this report.

Prospectus

Please fill this form and check your email for a link to download the prospectus. For a custom report on a topic of your choice or an updated version of an existing report, please contact us at +1 (281) 506-8234 or info@adi-cmr.com.