EPR and EPDM Technologies

Ethylene propylene rubber (EPR) and ethylene propylene diene monomer (EPDM) are versatile synthetic rubbers that are used in a variety of applications. EPR (sometimes called EPM) is a copolymer of ethylene and propylene. It has a saturated backbone chain, and is therefore, inherently resistant to degradation by heat, light, oxygen, and ozone. EPR is used in various markets including as a component of thermoplastic polyolefins (TPOs) and as oil additives. EPDM is produced by the copolymerization of ethylene and propylene plus a minor quantity of a nonconjugated diene termonomer, such as dicyclopentadiene (DCPD) or ethylidene norbornene (ENB). The diene allows EPDM to be crosslinked or vulcanized. EPDM offers a good combination of desirable properties including: (1) a saturated polymer backbone that provides excellent ozone and weathering resistance, low compression set, and good low temperature flexibility; (2) resistance to heat and oxidation; (3) good chemical resistance; (4) good electrical insulation; and (5) the ability to accept large amounts of low-cost solid filler and oil compared to other rubbers, while retaining a high level of compounded physical properties.

Market Drivers in the EPR and EPDM Market

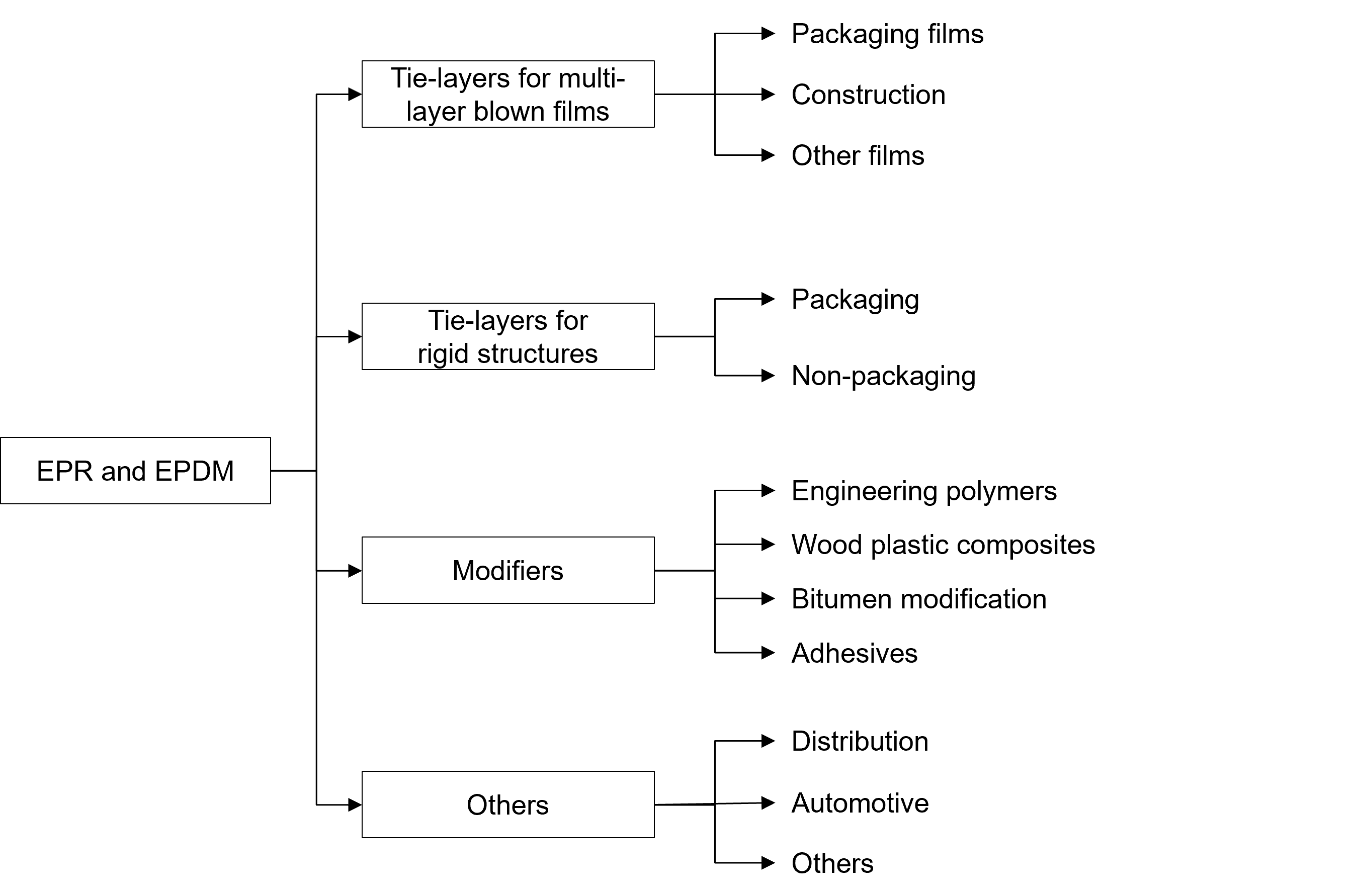

EPR and EPDM are used in a variety of applications including automotive parts, single-ply roofing membranes, TPOs, mechanical rubber goods, wire and cable, oil additives, tires and tubes, non-automotive hoses, and appliance parts. Other smaller volume applications include adhesives, pharmaceutical packaging, building and construction, and footwear. There has traditionally been very little inter-material competition in the EPDM market due to its superior impact, heat, and oil resistance properties. It is the dominant material used in automotive under-the-hood applications. Metallocene polyolefin elastomers (POEs) compete with EPDM as additives for modifying TPOs. North America and Western Europe have traditionally been the largest markets for EPDM, but domestic demand in Asia Pacific and China has been growing. Asia Pacific is expected to be the fastest growing regional market in terms of demand for EPR going forward. With changing lifestyle and increasing purchasing power especially in China and India, vehicle ownership is on the rise, which is positively influencing the EPR market in this region. Europe is the second-largest automotive manufacturing region, which drives the EPR market there. Exhibit 1 shows key end-use applications of EPR and EPDM driving demand.

Exhibit 1. EPR and EPDM applications

EPR and EPDM Market Assessment

ADI Chemical Market Resources (ADI CMR) has conducted a strategic analysis of current market dynamics and overview of industry growth drivers, with global and regional demand analysis forecast over the next five, 10, and 20 years. The report is based on thorough analysis of the industry through detailed interviews with all the major players including EPR and EPDM producers and end-users. The project will focus on market assessment over the time frame of 2015 to 2040, on an annual basis. The geographic focus of the market assessment will be regions segmented into North America, Latin (Central and South) America, Europe, Middle East and Africa, Asia Pacific, and China. The report will benefit: (1) present and future EPR and EPDM market participants; (2) polyolefin producers and compounders; (3) packaging industry participants; and (4) individual end-users, entrepreneurs, and organizations attempting to understand these complex issues and capture future growth in the marketplace.

Table of Contents

Click here for the table of contents for this report.

Prospectus

Please fill this form and check your email for a link to download the prospectus. For a custom report on a topic of your choice or an updated version of an existing report, please contact us at +1 (281) 506-8234 or info@adi-cmr.com.