Linear Alpha Olefins Technologies

Linear alpha olefins (LAOs), such as 1-butene, 1-hexene, and 1-octene, are used as comonomers in the manufacture of polyolefins, such as linear low-density polyethylene (LLDPE), high density polyethylene (HDPE), polyolefin elastomers (POE), and polyolefin plastomers (POP). Ethylene and propylene are the main monomers used for manufacturing polyolefins. The LAO comonomers define the final properties and thus the polymers use in various applications. LAOs are also used to manufacture intermediates that are used to produce various other chemicals such as butylene oxide, mercaptans, and aluminum alkyls. LAOs may be used to manufacture polyalphaolefins (PAOs), which are used to manufacture synthetic lubricants. LAOs are also used for the manufacture of oxo alcohols, which are produced from a hydrogenation of aldehydes that are formed by a reaction between olefins and syngas (CO + H2). The most common oxo alcohols are n-butanol and 2-ethyl hexanol (2-EH). Oxo alcohols are used in the manufacture of plasticizers, surfactants, acrylates, and solvents. LAOs can be produced via five manufacturing processes, which include oligomerization of ethylene, Fischer-Tropsch synthesis, dehydration of alcohol, metathesis, and dimerization of butadiene. The ethylene oligomerization route is the most widely used process for commercial production of LAOs. The better incorporation of comonomer leads to a lower amount of comonomer consumed and a better recovery efficiency. ADI CMR has also published reports on HDPE and POE/POP.

Market Drivers in the LAO Market

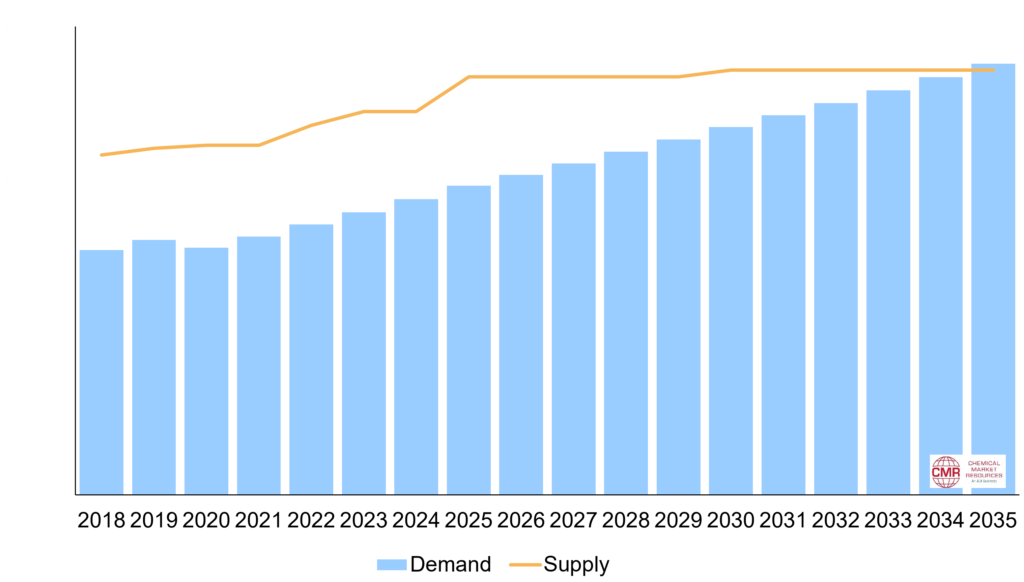

Based on ADI CMR’s monitoring of the olefins and polyolefins industry, the LAOs industry is going through changes pertaining to applications, trends, intermaterial competition, and technologies. For example, Shell Chemicals, the largest LAO producer, has a flexible production process that differs from the Ziegler-Natta catalyst-based process used by INEOS and Chevron Phillips Chemical. The Shell Higher Olefins Process (SHOP) integrates several chemical production techniques that allow Shell to maximize production economics of LAOs with synthetic long-chain detergent alcohols production. This process is flexible and can be adjusted based on changing demand. Exhibit 1 below illustrates how the balance of global LAO supply and demand is predicted to change over time. Exhibit 1 shows global LAO demand and supply outlook.

Exhibit 1. Global linear alpha olefins demand and supply outlook in kilo tons per year

LAO Market Assessment

ADI Chemical Market Resources (ADI CMR) has conducted a strategic analysis that covers all major developments in the industry including a comprehensive analysis of supply-demand balance, status of technology availability, and supplier analysis. The report is based on thorough analysis of the industry through a wide range of methods, including published information, patent searches, ADI CMR proprietary projects, and interviews with leading players including LAO producers as well as polymer and chemical producers and end-users. Robust predictive models were created to forecast market size and attractiveness based on input from experts and experienced ADI CMR analysts. The report will particularly benefit producers as well as individual end-users, entrepreneurs, and organizations attempting to understand these complex issues and capture future growth in the marketplace.

Table of Contents

Click here to view the table of contents for this report.

Prospectus

Please fill this form and check your email for a link to download the prospectus. For a custom report on a topic of your choice or an updated version of an existing report, please contact us at +1 (281) 506-8234 or info@adi-cmr.com.