- Version

- Download 0

- File Size 4.00 KB

- File Count 1

- Create Date June 14, 2024

- Last Updated June 14, 2024

Global Polypropylene Catalysts

Polypropylene Catalyst Technologies

Polypropylene (PP) is pre-dominantly produced using the ZN catalysts. Five generations of these catalysts have characterized the development of highly improved PP resins. The first two generation of ZN catalysts for PP are almost extinct, while the third generation is in the decline phase finding limited use. The fourth generation catalysts based on the phthalate internal donors are the most popularly used for producing a wide variety of PP resins. The fifth generation ZN catalysts based on the diether and succinate donors are fast becoming popular due to their improved productivity and enhanced isotacticity and stereo-control. The metallocene catalysts for PP have not made much of an impact, although commercial quantities of these resins are being produced.

Market Drivers in the Polypropylene Catalyst Market

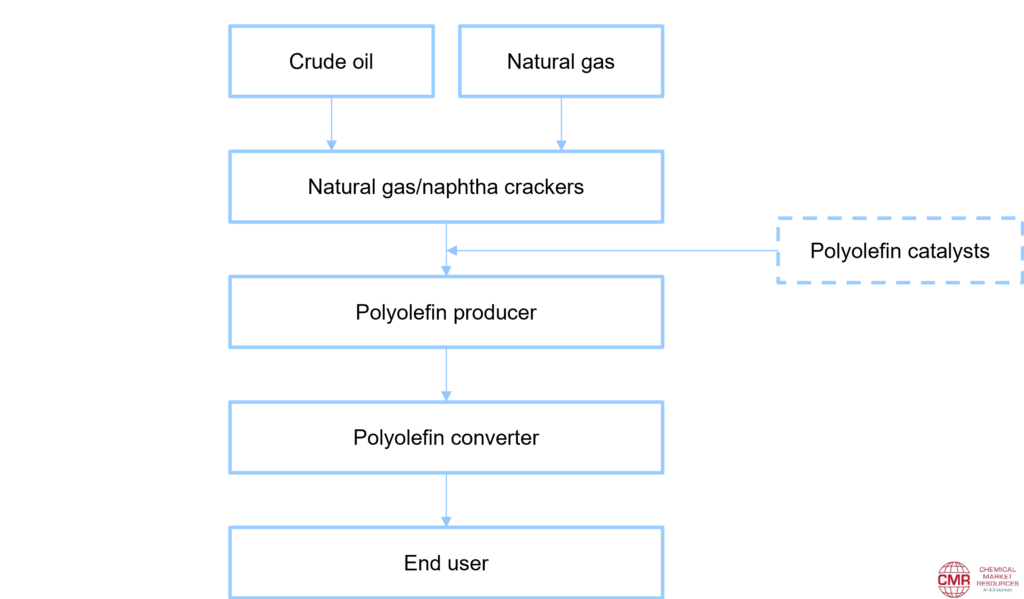

Polyolefin catalysts demand is driven by the demand for these materials in several end-use markets. The end-use markets driving the growth of PP catalysts include: 1) injection molding, 2) fiber & filament, 3) film applications, 4) Other extrusion, 5) blow molding, and others. The injection molding and fiber markets are the largest markets for polypropylene. Major applications involving injection molded PP include rigid packaging, consumer and industrial products, automotive, medical products, and others. The automotive market is a high growth market and requires use of impact co-polymers (ICP) which in turn require use of high mileage catalysts during the PP production process. The fiber & filaments application markets include spunbonded fibers, melt blown fibers, BCF/continuous, and others. Homopolymers (HPP) are the primary type of resin used in this market.The film and sheet applications are expected to drive global PP demand. Food packaging, tobacco packaging, industrial packaging, and shrink wrap are some of the end-uses in the film and sheet market.

Exhibit 1. Polyolefins value chain

Polypropylene Catalyst Market Assessment

ADI Chemical Market Resources (ADI CMR) has conducted a strategic analysis that covers all major developments in the industry including changing market dynamics, technology trends, evolving industry structure and strategic alliances, and the current and expected competitive landscape. Market forecasts are presented by region and application. This study will assess the relative position of each catalyst supplier in this niche, but dynamic and high-margin market. Another goal of this study is to review the catalyst needs per region and per process technology. The report is based on thorough analysis of the industry through a wide range of methods, including published information, patent searches, ADI CMR proprietary projects, and interviews with catalyst suppliers and resin producers. The report will particularly benefit polyethylene producers, and catalyst suppliers, as well as individual end-users, entrepreneurs, and organizations attempting to understand these complex issues and capture future growth in the marketplace. ADI CMR has specialized reports on the global markets for the polyolefin product families, including metallocene-catalyzed elastomers and plastomers, MDPE/HDPE, and PE catalysts.

Table of Contents

Click here to view the table of contents for this report.

Prospectus

Please fill this form and check your email for a link to download the prospectus. For a custom report on a topic of your choice or an updated version of an existing report, please contact us at +1 (281) 506-8234 or info@adi-cmr.com.